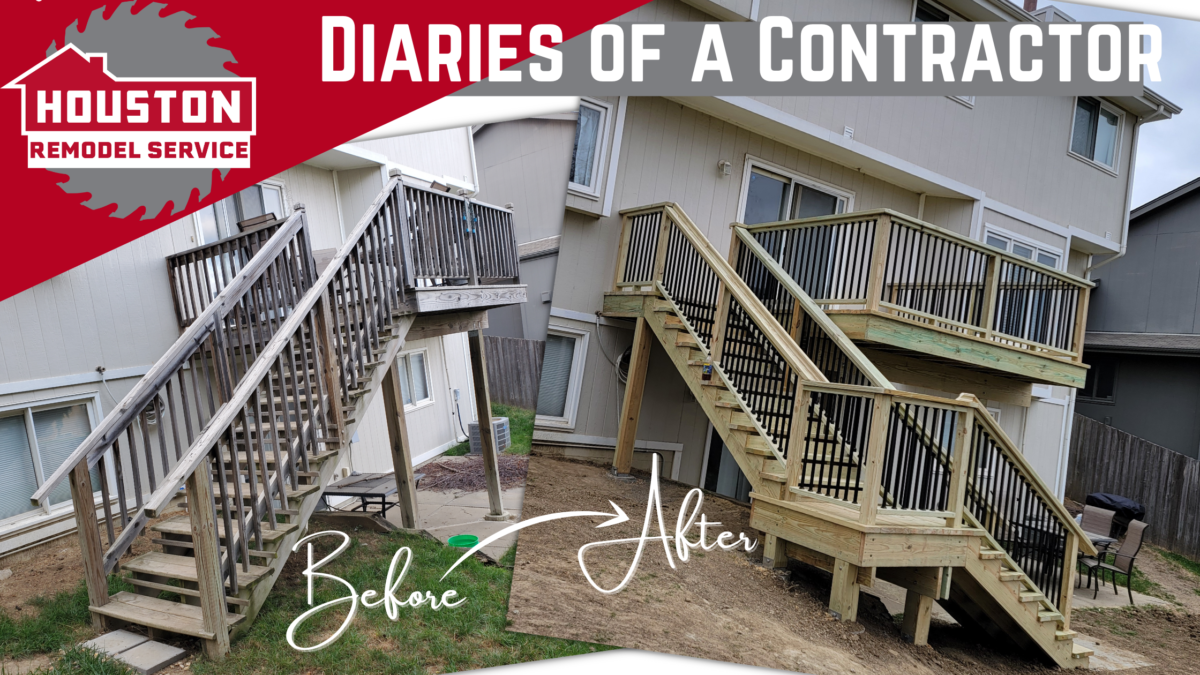

For our second blog in our Diaries of a Contractor series Mario wanted to tell us about a unique deck replacement project recently completed. The design presented interesting challenges to overcome in order to achieve a great result for the customer. Let’s take a look at the design, the materials used, how the process Houston takes differs from a DIY project and how Houston looks out for the legitimacy of your new construction.

The Design

As you can see from the before & after photos: this deck remodel included a redirection of the staircase which necessitated the installation of a landing partway through the staircase. This was more complex than typical deck replacement projects.

The Materials

For the materials used in the construction of the deck, we chose green-treated lumber and had an aluminum railing.

- Lumber: “Green treated” (aka pressure-treated) refers to wood that’s had preservatives forced into it, under pressure, to help protect it against decay and insect attacks. Pressure treated lumber will resist the elements better than untreated due to chemical preservatives added, which allows the wood to maintain its integrity in conditions that would cause normal wood to rot.

Pressure treated wood is long-lasting and a great investment for your family as it can last for up to forty years or more. Green timber has a naturally-pale, wooden color but you will also note a slight green tint or fleck caused by the pressure-treating process. The chemicals used in pressure treatment are copper based which react with both the sap of the timber and the air and then oxidize, creating green flecks on the surface.

- Railing: Aluminum railings are long-lasting and ideal for safety. They are lightweight and durable, and the best porch railing material for avoiding rust and corrosion. It is highly versatile with a sleek and stylish feel like no other deck railing material offers.

The Construction

What sets aside Houston from a DIY deck project are two main things: the wood used and the binding element.

Often homeowners will purchase custom decking boards for their project. These are typically very thin and not durable. When we construct a deck we use 2×6 wood planks instead. These helps the deck last longer and withstand the general wear and tear from use of the deck.

Another mistake homeowners make is using nails to construct the deck. Instead, we use screws in our construction. Screws are superior for laying down decking. They hold things flush better and have a better fastener strength, which keeps boards from popping up over time.

The Logistics

Many homeowners may not realize that you should go through the correct channels in your county or city when completing new construction, even on the exterior of your home. At Houston, we always pull the correct permits for deck construction so you can rest assured that any project with Houston is up to current code. All our decks are inspected by a county or city official when it’s completed as well as part of the process.

In the end, the customer was left with a beautiful and durable deck for their home. At Houston, we will always ensure high quality projects that will leave homeowners feeling satisfied.

Let Houston Help Build a Deck that Lasts

Is your deck or outdoor space ready for a remodel? Contact Houston Remodel Service today to get started! Our contractor services are professional, quick and honest.